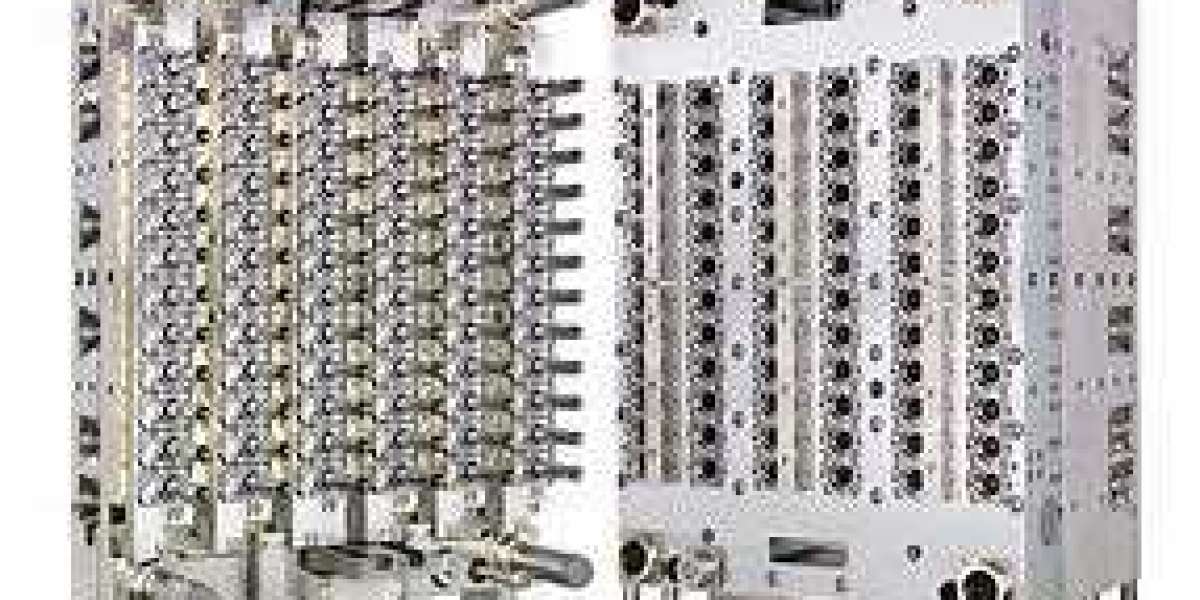

In the world of beverage packaging, the unsung hero is often the humble bottle cap. Behind the scenes, bottle cap moulds and water bottle cap moulds play a important role in ensuring the reliability, functionality, and efficiency of these small yet important components. This article explores the intricacies of bottle cap moulds and their specialized counterpart, water bottle cap moulds, shedding light on the craftsmanship that goes into creating these precision-engineered pieces.

Bottle Cap Moulds:

Bottle cap moulds are instrumental in the manufacturing process of bottle caps, serving as the blueprint for creating these important closures. The meticulous design and construction of these moulds determine the quality, durability, and functionality of the final bottle caps.

Key Features of Bottle Cap Moulds:

1. Material Compatibility: Bottle cap moulds are crafted with careful consideration of the materials used in the manufacturing process. They must be compatible with a variety of materials, including plastics like polyethylene and polypropylene commonly used in bottle cap production.

2. Precision Engineering: The design of bottle cap moulds involves precision engineering to ensure the accurate and consistent formation of caps. This precision is important for maintaining the integrity of the seal and the overall functionality of the bottle cap.

3. Durability: The durability of bottle cap moulds is important, given the high production volumes they endure. These moulds must withstand repeated use and the pressures of injection molding processes to ensure longevity and cost-effectiveness.

4. Versatility: Bottle cap moulds are versatile, accommodating different cap styles, sizes, and designs. This adaptability allows manufacturers to produce a diverse range of bottle caps for various beverage containers.

Applications of Bottle Cap Moulds:

1. Carbonated Beverages: Bottle cap moulds are extensively used in the production of caps for carbonated beverage bottles. The tight seal they provide is important for retaining carbonation and freshness.

2. Non-Carbonated Drinks: From water to fruit juices, bottle cap moulds cater to the diverse range of non-carbonated beverages. Their precision ensures a reliable seal, preserving the quality of the contents.

3. Pharmaceutical Packaging: Bottle cap moulds find application beyond the beverage industry, contributing to the production of caps for pharmaceutical containers. The same precision and reliability are important for maintaining the integrity of pharmaceutical products.

Water Bottle Cap Moulds:

Water bottle cap moulds are a specialized category designed specifically for the important requirements of water bottle caps. As water bottles have become ubiquitous in our daily lives, the demand for precision-engineered water bottle cap moulds has risen to ensure the safety and freshness of the contained water.

Key Features of Water Bottle Cap Moulds:

1. Tamper-Evident Features: Many water bottle cap moulds incorporate tamper-evident features to assure consumers of the integrity of the bottled water. These features provide visible indicators of whether the bottle has been opened or tampered with.

2. Sealing Efficiency: Water bottle cap moulds prioritize sealing efficiency to prevent leakage and contamination. The design ensures a tight seal that preserves the purity and freshness of the water throughout its shelf life.

3. Material Selection: Water bottle cap moulds are designed to work seamlessly with materials approved for use in bottling water. This often involves considerations related to food-grade plastics and compliance with health and safety regulations.

4. Customization Options: Manufacturers of water bottle cap moulds understand the importance of branding and differentiation. As a result, these moulds offer customization options, allowing for the incorporation of logos, brand names, and other design elements on the caps.

Applications of Water Bottle Cap Moulds:

1. Single-Use Water Bottles: Water bottle cap moulds are primarily used in the production of caps for single-use water bottles. The tamper-evident features and sealing efficiency are important for assuring consumers of the safety and freshness of the water.

2. Bulk Water Packaging: In addition to single-use bottles, water bottle cap moulds cater to the production of caps for larger, bulk water packaging. These may include gallon-sized containers commonly used in homes and offices.

3. Sports and Fitness Bottles: The versatility of water bottle cap moulds extends to the production of caps for sports and fitness bottles. The tamper-evident features remain relevant, providing assurance to consumers in various contexts.

Comparative Analysis:

When comparing bottle cap moulds and water bottle cap moulds, it's evident that both serve important roles in the beverage packaging industry. Bottle cap moulds, with their versatility, are suitable for a broad range of beverages, including carbonated drinks, non-carbonated beverages, and pharmaceutical products. Their precision engineering ensures reliable sealing and durability.

On the other hand, water bottle cap moulds address the specific needs of water packaging, emphasizing features like tamper-evidence and sealing efficiency. These moulds are tailored to meet the stringent requirements of the bottled water industry, where freshness and safety are important.

Conclusion:

In the intricate dance of beverage packaging, bottle cap moulds and water bottle cap moulds take center stage, influencing the quality, functionality, and safety of the final products. From the fizz of carbonated drinks to the purity of bottled water, these moulds contribute to the seamless and reliable closure of containers that accompany us in our daily lives.

The craftsmanship embedded in bottle cap moulds and water bottle cap moulds showcases the intersection of precision engineering and material science. As consumers, we may not often ponder the meticulous design behind a bottle cap, but the reliability and efficiency of these moulds are important contributors to the satisfaction and trust we place in the beverages we consume. As technology and innovation continue to advance, we can anticipate further refinements in bottle cap moulds, ensuring that the artistry behind these small yet significant components continues to evolve in tandem with our changing needs and expectations.