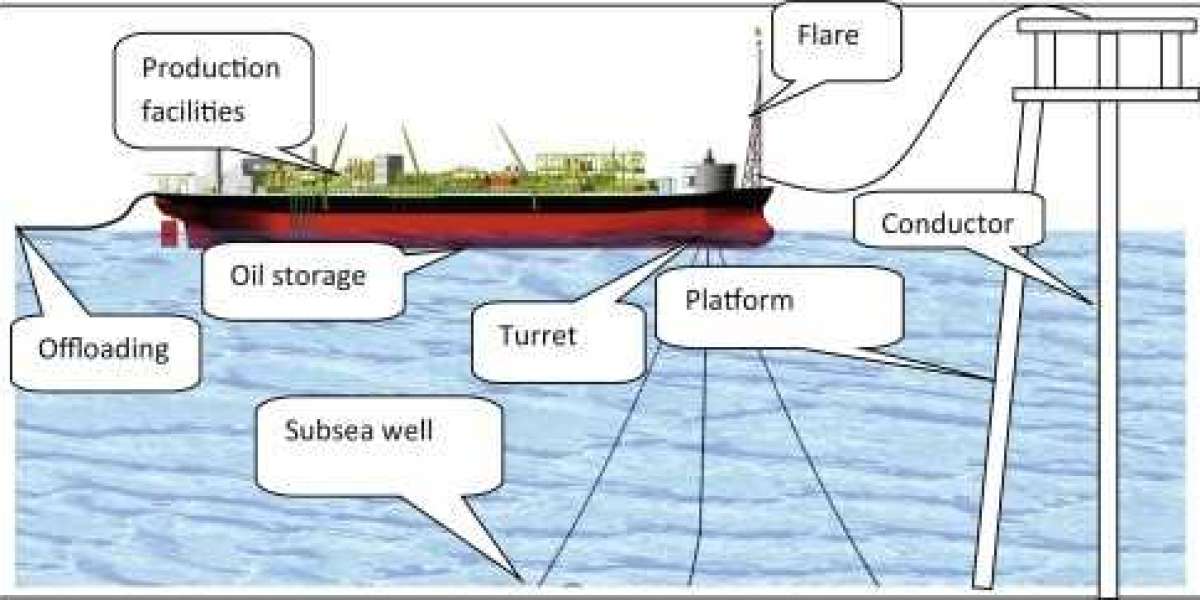

Heat exchangers are essential components of Floating Production, Storage, and Offloading (FPSO) systems because of the particular difficulties associated with offshore oil and gas operations. Heat exchangers are necessary for FPSOs for the following reasons:

Facilities for processing hydrocarbons, such as natural gas and crude oil, that are drawn from offshore wells are installed on FPSOs DESIGNING SHELL AND TUBE HEAT EXCHANGERS FOR FLOATING PRODUCTION STORAGE AND OFFLOADING (FPSO) HEAT EXCHANGERS MANUFACTURER. Heat exchangers play a critical role in processes like treating and separating hydrocarbon streams, condensing vapours, and regulating temperature at different stages of processing.

Temperature control is essential to FPSO operation efficiency. In order to maintain the ideal range for processing and storage conditions, heat exchangers assist in controlling the temperature of process fluids.

For machinery and other equipment like gas compressors, FPSOs frequently need cooling systems. Equipment overheating is avoided via heat exchangers, especially air coolers and finned tube heat exchangers, which dissipate excess heat produced during compression.

Boilers are usually used by FPSOs to produce steam, which is necessary for a number of operations, including heating and power generation. These boilers’ feedwater is preheated by heat exchangers, which increases energy efficiency and lowers fuel usage.

Common FPSO tasks include processing generated water, separating gases, and condensing vapours. Heat exchangers play a crucial role in these procedures by guaranteeing effective heat transfer and enabling the phase shifts required for treatment and separation.

Weight and space restrictions pose serious problems for FPSOs. Heat exchangers must be made to be lightweight, small, and able to withstand the demanding thermal requirements of the vessel’s numerous processing units.

FPSOs work in harsh offshore conditions with exposure to saltwater, strong winds, and possible wave movement. It is necessary to use materials and coatings in the design of heat exchangers that are resistant to corrosion and degradation under these circumstances.

Strict safety requirements and standards must be followed by FPSOs. Heat exchangers are essential for preserving safe working conditions, and in order to assure compliance and prevent accidents, safety features must be incorporated into their design.