Custom walking beams are an essential component in many industrial applications, providing a reliable and efficient means of transporting heavy loads. These beams are designed to meet the specific needs of each individual customer, ensuring that they are tailored to the unique requirements of their operation. Whether you need a walking beam for a manufacturing facility, a warehouse, or a construction site, a custom solution can be designed to meet your exact specifications. In this article, we will explore the benefits of custom walking beams and how they can be tailored to your unique needs.

Understanding the Basics: What are Custom Walking Beams?

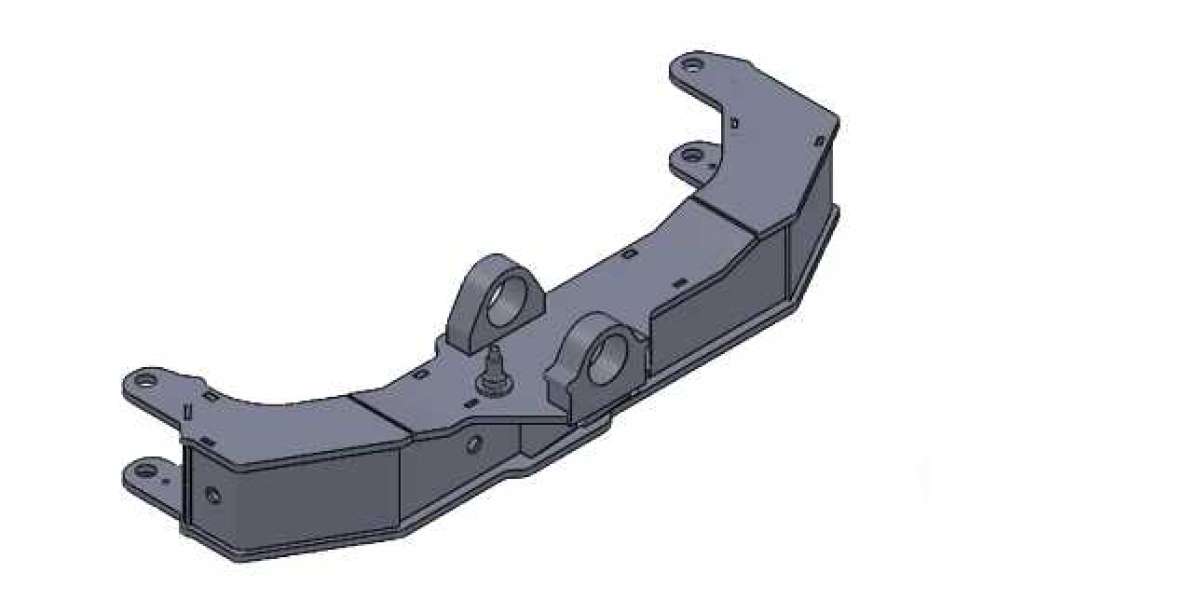

Custom walking beams are a type of mechanical device commonly used in various industries for lifting and moving heavy loads. They consist of two parallel beams connected by cross members, creating a stable platform that can support the weight of the load.

These beams are designed to evenly distribute the weight across multiple points, reducing stress on individual components and providing greater stability during operation. The design and dimensions of custom walking beams can be tailored to meet specific requirements, making them versatile for different applications.

One key advantage of using custom walking beams is their ability to handle large or irregularly shaped loads with ease. By adjusting the length, width, and height of the beams, manufacturers can create a solution that precisely matches the unique needs of each customer.

Another benefit is improved safety. Custom walking beams provide reliable support and control during lifting operations, minimizing the risk of accidents or damage to equipment. Additionally, they offer enhanced maneuverability due to their flexibility in design.

When choosing a custom walking beam, several factors should be considered such as load capacity requirements, environmental conditions, operating conditions, and any specific industry regulations that must be followed.

The process of designing and manufacturing a custom walking beam typically involves collaboration between engineers and customers. This ensures that all specifications are met while also taking into account any practical limitations or constraints.

Custom walking beams offer numerous advantages over standard options when it comes to lifting heavy loads safely and efficiently. By understanding their basic principles and considering various factors in choosing an appropriate design, businesses can optimize their operations while ensuring worker safety.

Benefits of Using Custom Walking Beams

When it comes to industrial machinery, having the right equipment can make all the difference. Custom walking beams are a prime example of this. These specially designed beams offer a range of benefits that can greatly enhance your operations.

One major advantage of using custom walking beams is their versatility. Unlike standard walking beams, which are designed for general use, custom options can be tailored to meet your unique needs. This means you can have a beam that perfectly fits your specific application and requirements.

Another benefit is improved efficiency and productivity. Custom walking beams are built with precision and attention to detail, ensuring optimal performance and smooth operation. This not only reduces downtime but also increases overall productivity by allowing for faster and more efficient material handling.

Additionally, custom walking beams offer enhanced safety features. With tailor-made designs, these beams can incorporate specialized safety mechanisms such as sensors or alarms to prevent accidents or malfunctions during operation.

Furthermore, using custom walking beams often results in cost savings over time. By investing in equipment specifically designed for your needs, you reduce the risk of damage or wear caused by incompatible components or improper usage.

In conclusion, utilizing custom walking beams brings numerous advantages including increased versatility, improved efficiency and productivity, enhanced safety features, and potential cost savings in the long run.

Factors to Consider when Choosing a Custom Walking Beam

When it comes to choosing a custom walking beam, there are several factors to keep in mind. These factors can help ensure that you find the right walking beam for your specific needs and requirements.

It is important to consider the load capacity of the walking beam. This refers to the maximum weight that the beam can support safely. It is crucial to choose a walking beam with a load capacity that matches or exceeds your anticipated workload.

You should take into account the size and dimensions of the walking beam. The length, width, and height need to be carefully considered based on your intended application. A properly sized walking beam will provide optimal stability and performance.

Another factor worth considering is the material used in manufacturing the walking beam. Different materials have varying levels of strength and durability. Selecting a material that meets your desired level of sturdiness is essential for ensuring longevity and reliability.

Additionally, think about any special features or attachments you may require for your custom walking beam. Whether it's adjustable legs or additional supports, make sure these features align with your specific needs.

Don't forget about cost considerations when choosing a custom walking beam. Compare prices from different manufacturers and suppliers while keeping in mind that quality often comes at an added expense.

By taking these factors into consideration during the selection process, you can ensure that you end up with a custom walking beam perfectly tailored to meet all of your unique needs!

The Process of Designing and Manufacturing a Custom Walking Beam

The process of designing and manufacturing a custom walking beam begins with a thorough understanding of the customer's unique needs and requirements. This involves gathering information such as load capacity, operating conditions, and any specific design specifications.

Once this information is gathered, the design team can begin creating a concept for the custom walking beam. This typically involves using specialized software to create detailed 3D models that allow for precise engineering calculations and simulations.

Next, the design is reviewed by engineers and experts in order to ensure its feasibility and functionality. Any necessary modifications or adjustments are made at this stage to optimize performance.

Once the final design is approved, it moves into the manufacturing phase. Skilled technicians use state-of-the-art equipment to fabricate each component of the custom walking beam according to precise specifications.

Quality control measures are implemented throughout every step of the manufacturing process to ensure that each component meets rigorous standards. This includes inspections, testing, and certification procedures.

Once all components have been manufactured and inspected thoroughly, they are assembled together to complete the custom walking beam. The finished product undergoes one last round of quality checks before being delivered to the customer.

In conclusion, designing and manufacturing a custom walking beam is a complex but crucial process that requires expertise in engineering principles as well as skilled craftsmanship. By tailoring each aspect of the design specifically for individual needs, customers can enjoy enhanced performance and efficiency in their operations.

Conclusion

Custom walking beams offer numerous benefits and advantages for various industries. These specialized devices are tailored to meet specific needs and requirements, ensuring optimal performance and efficiency.

By understanding the basics of custom walking beams and considering important factors such as load capacity, size, materials, and design preferences, businesses can make informed decisions when choosing the right solution for their operations.

The process of designing and manufacturing a custom walking beam involves collaboration between engineers, designers, and manufacturers to create a product that meets all specifications. This ensures that the final result is a high-quality device that delivers exceptional performance in even the most demanding applications.

Whether used in heavy machinery or precision equipment, custom walking beams provide stability, control over movement, increased load capacity, reduced wear on components, improved safety measures—all contributing to enhanced productivity and cost-efficiency.

Discover how custom walking beams can revolutionize your operationsand take your business to new heights!