Introduction

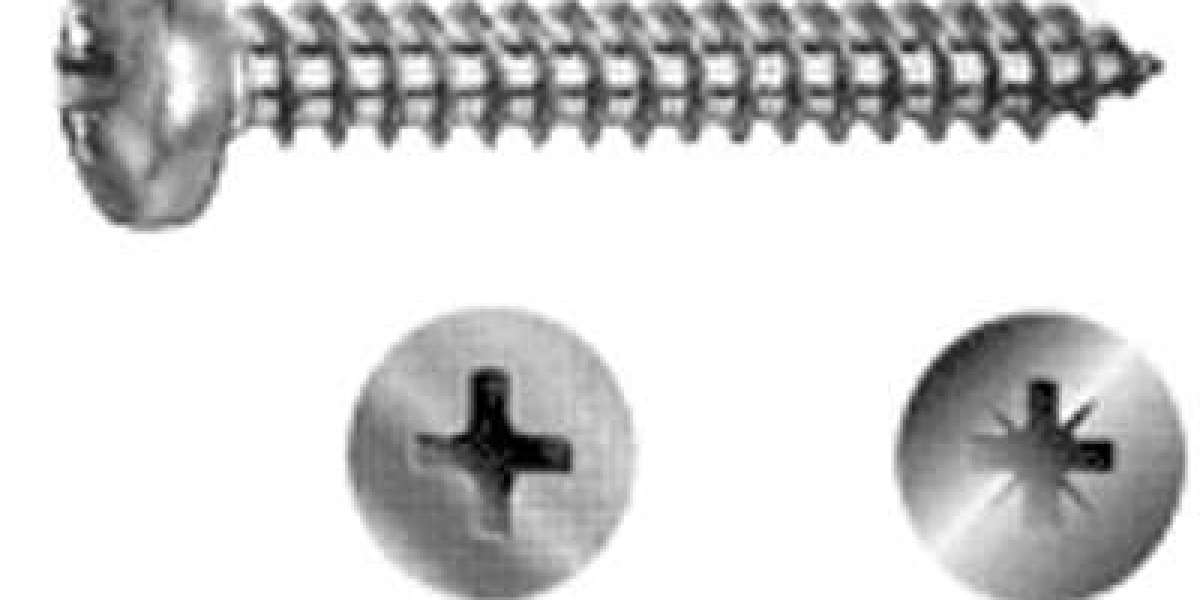

When it comes to fasteners, the world of screws is a fascinating one. Among the myriad types of screws available, the cross recessed tapping screw stands out as a versatile and indispensable choice for various applications. In this article, we will explore the cross-recessed tapping screw, its features, applications, and address some frequently asked questions to help you understand its significance better.

FAQ Section

1. What is a Cross-Recessed Tapping Screw?

A cross-recessed tapping screw, also known as a Phillips screw, is a type of screw that features a cross-shaped indentation on its head, which allows for easy installation and removal. The screw is designed to create its own threads within a material when driven, making it a valuable tool in various industries.

2. What Are the Key Features of Cross-Recessed Tapping Screws?

Cross-recessed tapping screws have several distinguishing features:

Cross-shaped Recess: The prominent cross-shaped recess on the screw head provides a secure grip for the screwdriver or bit, minimizing the risk of slipping during installation.

Self-Tapping: These screws are designed to create threads as they are screwed into a material, eliminating the need for pre-drilling holes.

Versatility: Cross-recessed tapping screws are suitable for a wide range of materials, including wood, metal, plastic, and more.

Various Sizes: They are available in various sizes and lengths to accommodate different projects and applications.

3. What Are the Common Applications of Cross-Recessed Tapping Screws?

These versatile screws find application in many areas, including:

Woodworking: They are commonly used in carpentry and furniture making, where they offer a strong, secure hold in wooden materials.

Construction: In construction, these screws are used to fasten drywall, gypsum board, and other building materials to metal or wood studs.

Automotive: Cross-recessed tapping screws are essential in the automotive industry for assembling various components.

Electronic Devices: Many consumer electronic devices use these screws for assembling and repairing.

General Repairs: For household repairs and DIY projects, these screws are often the go-to choice.

4. How Do I Choose the Right Size of Cross-Recessed Tapping Screw?

Selecting the right size is crucial for a secure and efficient fastening. To determine the appropriate size:

Measure the thickness of the material you are fastening.

Ensure that the screw length is sufficient to penetrate the material and leave enough thread for a strong grip.

Match the screw's diameter (gauge) to the material's thickness.

5. Are There Any Tips for Using Cross-Recessed Tapping Screws Effectively?

To ensure successful installation, keep these tips in mind:

Use a compatible screwdriver or bit to avoid damaging the screw head.

Apply steady and even pressure while driving the screw to prevent stripping or damaging the material.

Pre-drill holes for harder materials like metal to facilitate easier screw insertion.

6. Are There Any Variations of Cross-Recessed Screws?

Yes, there are variations of the cross-recessed screw, including:

Phillips: The most common type, with a standard cross-shaped recess.

Pozidriv: Similar to Phillips but with additional star-shaped features for improved grip.

Frearson: A less common type, similar to Phillips, primarily used in marine applications.

Tamper-Resistant: Designed to deter tampering, these screws have unique recess patterns.

In conclusion, the cross-recessed tapping screw is a versatile and essential fastener used in various industries and applications. Understanding its features, applications, and proper usage will help you make the most of this reliable and widely-used screw type. Whether you are a DIY enthusiast, a professional tradesperson, or simply someone who occasionally needs to fasten materials, the cross-recessed tapping screw is a valuable tool in your arsenal.