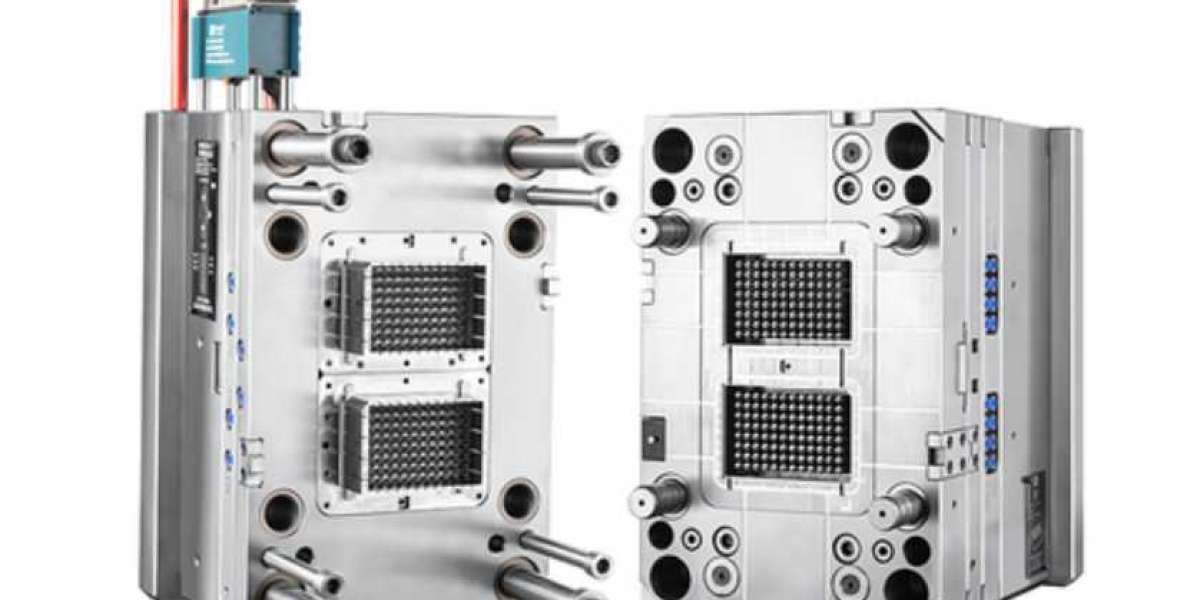

Medical device plastic molding is a crucial manufacturing process that enables the production of a wide range of medical devices using plastic materials. This process involves melting plastic and injecting it into molds to create specific shapes and designs.

The primary advantage of medical device plastic molding is its ability to produce highly detailed and complex components with exceptional accuracy. This precision is essential for medical devices, which must meet strict performance and safety standards. The process can handle a variety of medical-grade plastics, each selected for properties such as biocompatibility and the ability to withstand sterilization.

Furthermore, medical device plastic molding is an efficient method for mass production. It allows manufacturers to produce large volumes of devices quickly and at a lower cost, making healthcare products more accessible. The scalability of this process is beneficial for meeting the high demand for medical supplies and devices.

Quality assurance is a critical component of medical device plastic molding. Manufacturers implement comprehensive testing and validation protocols to ensure that each device meets regulatory standards and performs reliably. This rigorous approach to quality control helps maintain the safety and effectiveness of medical devices.

In summary, medical device plastic molding is a vital process in the healthcare industry, enabling the production of precise, high-quality devices efficiently and cost-effectively. Continuous advancements in molding technology and materials will further enhance the capabilities of this essential manufacturing method.